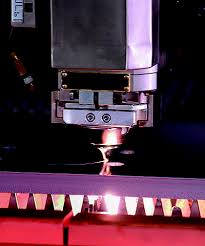

Mica Laser Cutting is a profoundly powerful innovation that can be utilized to cut an assortment of intense and safe material including carbon and hardened steel, aluminum, copper composites and so on. The metal creation industry utilizes this innovation broadly in the cutting and creation of sheet metal. This cutting innovation incredibly upgrades speed of efficiency, diminishing creation costs, and working on nature of cutting. The Mica Laser Cutting innovation depends on the discharge of a light bar through a course of feeling and uses a gadget that is known as a laser or LASER, short for Light Amplification by Stimulated Emission of Radiation. The business utilizes various lasers in view of the cycle they use to transmit light pillars. The most widely recognized ones incorporate carbon dioxide laser or CO2 laser, which is a gas laser utilized expansively for welding across the business. This sort of lasers can deliver a limit of 100 KW of energy at 9.6 µm and 10.6 µm and can cut 20-30 meters of materials that are 1 mm thick in a moment.

While cutting the energy that is delivered is focused on a little piece of the material to be sliced to create an opening, the light pillar is then moved along the line to finish the cut. Frequently, obviously when the material is sufficiently convenient the material is gotten across where a constant flow of light is anticipated. Where the strong light emission strikes the sheet metal it rapidly warms up, liquefies, and vanishes. How much energy conveyed through the lasers relies upon the sort of material that should be cut. Materials that are slender require lesser measure of energy to be created. Notwithstanding, on a normal 1 to 1.5 KW of energy is sufficient bang mica de ban cut most materials, while steel and a few other safe materials require 2 KW or a greater amount of energy.

There are a few benefits of utilizing Mica Laser Cutting administrations, similar to precision, nature of the task finished, speed of cutting, and moderateness. These benefits alone make lasers cutting administrations the most famous cutting assistance in the sheet metal creation industry. In any case, there are not many burdens of involving lasers for cutting metal; for example, lasers require extremely high voltage to work and aside from high power utilizations lasers likewise make you risk consumes or electric shock, so far as that is concerned. Yet, given the advantages of involving laser as an innovation for the cutting of sheet metal, nothing unexpected despite the hindrances an enormous number of organizations across the business proceed to client Mica Laser Cutting innovation to further develop speed and accuracy of their work.